Project Background

Client Company: A large manufacturing enterprise;

Industry: High-end equipment manufacturing / Heavy machinery processing;

Application scenario: Precision inspection of large boring and milling machining centers.

The company has a large boring and milling machining center for processing large equipment components. This machine tool simultaneously completes processes such as milling, drilling, and boring.

To ensure the accuracy of processed parts and product quality, it is necessary to inspect the dimensional accuracy of the parts both online and offline.

Customer Challenges and Pain Points

1. Large-scale measurement: Parts can be up to 5 meters long, and traditional coordinate measuring machines cannot meet the online size control and measurement requirements for large dimensions (such as coaxiality, parallelism, etc.);

2. Online Detection: The purpose of detection is not only to verify the accuracy of the machine tool but also to quickly locate the source of errors, clarify the status of the parts, and ultimately ensure the accuracy of the dimensions after the parts are offline;

3. Complexity of Workshop Environment: The workshop is subject to interference factors such as vibration and temperature fluctuations, which pose challenges for high-precision measurements.

Figure 1: Radian Core Laser Tracker

Figure 2: API Series Laser Trackers (from left to right: Radian Plus / Radian Pro / Radian Core / iLT)

Solution

After comprehensive evaluation, the client company chose the API Radian Core laser tracker system as the solution.

Core Equipment: The API Radian Core laser tracker offers micron-level measurement accuracy and a measurement radius of up to 80 meters, meeting the needs for large machine tool detection;

High-Precision Target Sphere (SMR): Used for contact measurement, reflecting laser beams;

Portable Control Unit and Measurement Software: Used to control the tracker, collect data, and automatically generate analysis reports.

On-Site Implementation

1. Detection planning and equipment layout: Based on the dimensions of the parts to be tested, position the laser tracker in a location where all axis movements are visible. The Radian Core laser tracker is highly portable (equipment weight < 11kg) and can be quickly deployed at assembly stations or workshop sites.

2. Data Collection: By selecting reasonable tracking instrument positions based on the measurement requirements of the parts, the dimensions of the shaft holes are measured. The reasonable arrangement of the rotating station allows for the movement of the tracking instrument positions, ensuring both the accuracy of the positions and the integration of the detected data. The software's temperature compensation system eliminates the hassle of waiting for constant temperature measurements of the parts.

Figure 3: Photo of Laser Tracker Field Measurement

Data Analysis and Report Generation

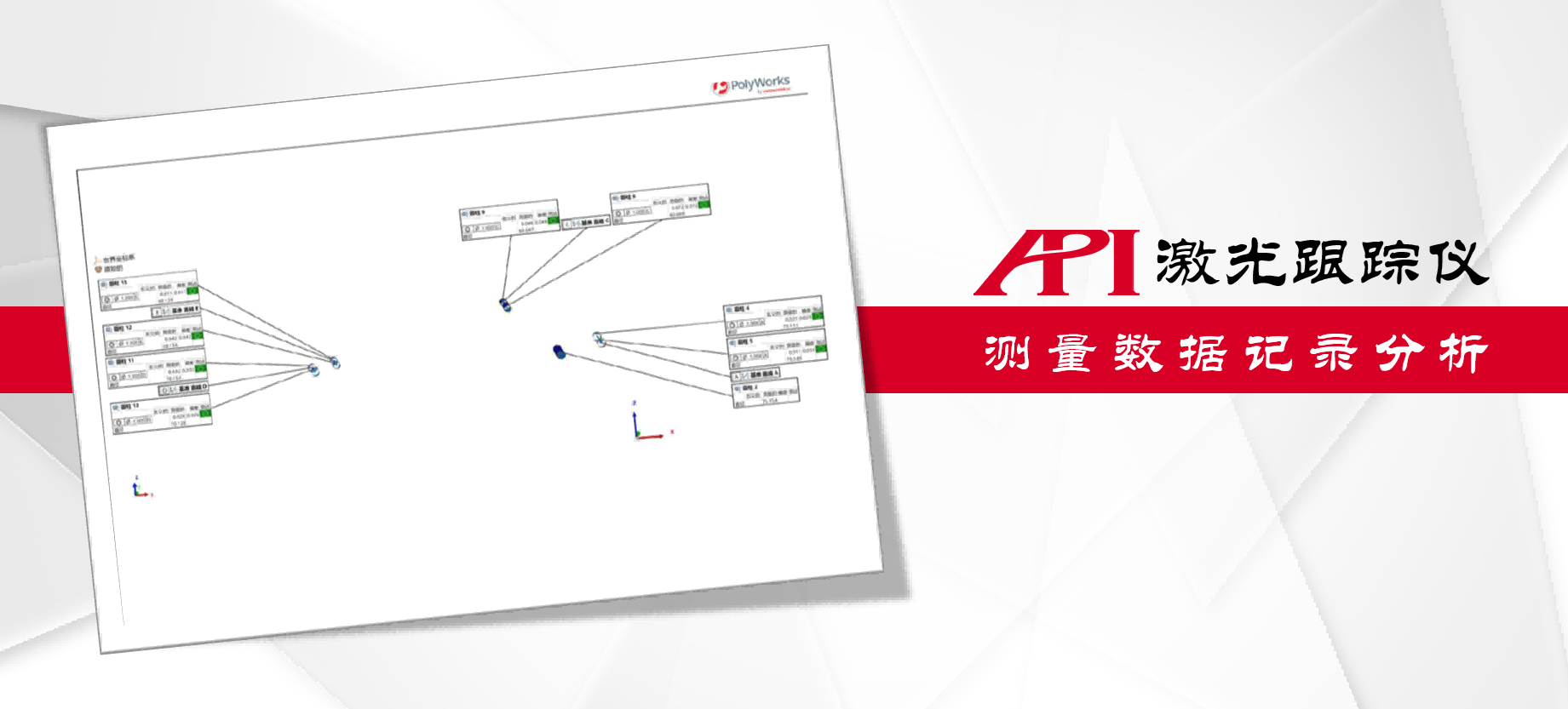

Using Polyworks measurement software, the collected spatial coordinate data is automatically analyzed to determine the diameters of various holes, coaxiality dimensions, relative position dimensions, and other technical requirements of the parts as requested by the customer. The software automatically generates intuitive analysis reports (including data lists, curve graphs, error cloud maps, etc.).

In addition to the Polyworks measurement software used in this case, the API series laser trackers are widely compatible with most measurement software, such as SA, Metrolog, Verisurf, etc. API has also independently developed the MeasurePro measurement software based on the characteristics of its instruments and frontline application experience, enabling integrated applications and unified data analysis across the entire range of equipment.

Figure 4: Measurement Data Recording and Analysis (Measurement Report)

Results and Benefits Achieved

After introducing the API Radian Core laser tracker system, the company has achieved significant results in the inspection and maintenance of large machine tools.

1. Significant Improvement in Inspection Efficiency: Compared to traditional inspection methods, the inspection efficiency has been reduced by over 70%. Parts that previously required 1-2 days for precision inspection can now be completed in just half an hour, greatly reducing machine downtime;

2. High Inspection Accuracy and Reliability: The laser tracker provides micron-level measurement accuracy, and its built-in temperature compensation module effectively offsets the impact of temperature changes in the workshop environment on measurement results, ensuring the accuracy and reliability of the inspection data;

3. Precise Guidance: The automatically generated detailed inspection report not only accurately reflects the current precision status of the parts but also provides a preliminary assessment of the machine tool's processing state and compensation processing parameters.

Conclusion and Outlook

Practice shows that high-precision laser trackers are ideal tools for solving the precision and efficiency challenges in the detection of components for large machine tools and oversized workpieces. They can replace various traditional inspection tools, achieving fast and accurate multidimensional measurements, and provide precise guidance for equipment maintenance through intuitive data analysis. This is an important step for machining enterprises towards digital and intelligent quality management.

In the future, with technological advancements, the integration of laser trackers and machine tool control systems will become closer, promising real-time error compensation and closed-loop control during the processing, further promoting the machining industry towards ultra-high precision and intelligence.

Figure 5: API Company Headquarters Building

About API

The API brand was founded by Dr. Kam Lau in 1987 in Rockville, Maryland, USA. He is the inventor of the laser tracker and holds multiple patents for globally leading measurement technologies, making him a leader in the field of precision measurement technology. Since its establishment, API has been dedicated to the research and production of precision measuring instruments and high-performance sensors in the mechanical manufacturing field. Its products are widely used in advanced manufacturing sectors around the world and are at the forefront of high-precision standards in coordinate measurement and machine tool performance testing.

相关新闻:

API laser tracker is Application in the Inspection of Medium and Large Machined Parts

Project BackgroundClient Company: A large manufacturing enterprise;Industry: Hig

Radian laser tracker at Bucyrus 495HR Application of Mining Excavator Maintenance

Overview of Bucyrus 495HR Mining Excavator and Maintenance The Bucyrus 495HR min

Aerospace Composite Material Laying System Precision Detection Radian Laser Tracker Application Cas

About Aerospace Composite MaterialsAerospace composite materials are primarily u

3D Measurement Solutions for Large Oil Equipment

3D Measurement and Inspection of Large Oil EquipmentIn the oil equipment manufac

Learn More:

激光跟踪仪靶球&测头

Maximize laser tracker productivity with hand held and 激光跟踪仪主动靶标.

Learn More /laser-tracker-targets

XD Laser CMM Calibration

The XD Laser is the only assessment system that can measure all 6 error parameters simultaneously in a single set-up

Learn More /xd-laser

API Reverse Engineering Service

Reverse engineering services include scan as-built parts to creation of a 3D digital point cloud and CAD Model.

Learn More /reverse-engineering/

+86 10 59796858

+86 10 59796858