Our Customers

Our customer is a large-scale integrated production and supply chain enterprise that provides matching large and extra-large standardized and non-standard castings for the manufacturing of heavy-duty equipment. Their products cover fields such as mining machinery, metallurgical equipment, ship components, bridge structural components, large motor components, and more. This includes the production of standard or non-standard workpieces such as flanges, gears, belts, half-tooth rings, end covers, beams, slag pouring, rolling mill baffle, rudder arm, shaft, bridge seat plate, and cable saddle, etc.

Customer's Measurement Needs, Difficulties, and Issues

With the update of market demand and the continuous improvement of manufacturing standards, there is an increasing demand for the precision and efficiency of 3D detection of large and extra-large castings. This requires more precise and efficient measurement methods and equipment to assist in meeting the enhanced measurement requirements.

Due to the limitations of traditional measurement methods, the customer contacted the API team, hoping to optimize their measurement and detection process with more advanced detection methods to ensure a double harvest of production quality and efficiency.

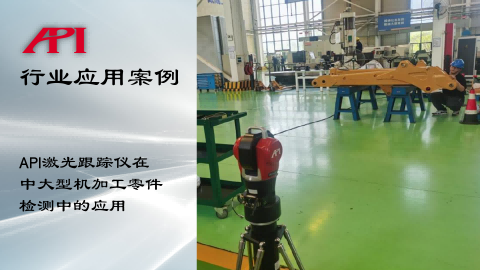

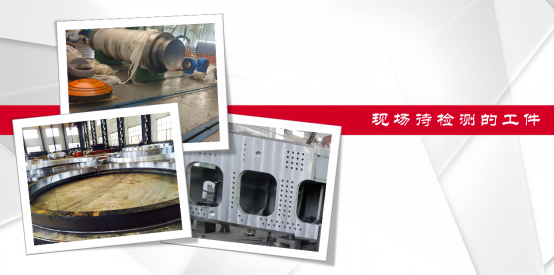

Figure 1: The workpiece to be measured on the site of this case

The customer's current detection needs are based on the following three types of workpieces:

Measurement of the inner diameter of the annular sleeve

The inner diameter of the test sleeve reaches 10 meters, with high material strength, overall processing, and no welding or assembly. The customer needs to carry out precise three-dimensional detection of the inner diameter of this model of sleeve. Traditional measurement methods involve using two large and heavy large-scale inner diameter micrometers in coordination, one on the left and one on the right, making the measurement operation very inconvenient. Moreover, due to the large span of measurement required, the middle part of the inner diameter micrometer is prone to deformation and sagging under its own weight, making it difficult to guarantee the actual measurement accuracy. Additionally, the measurement process is greatly influenced by personnel operation and experience, making it relatively objective.

Detection of position tolerance of non-standard workpiece holes and form and position tolerance data of connection surfaces

The second measurement requirement of the customer is to measure the position relationship of the connection surfaces of the non-standard workpieces produced, as well as the position tolerance of the holes on the workpieces, and compare the measurement data with the drawing dimensions. Due to the large size and weight of the workpieces, using traditional measurement tools or instruments such as coordinate measuring machines or articulated arms will be affected by factors such as measurement distance, accumulated error, measurement environment, time, and labor costs to varying degrees, resulting in unsatisfactory results.

Three-dimensional measurement and theoretical data comparison for curved surfaces

Finally, in this measurement, the customer also hopes to carry out three-dimensional measurement and detection of some workpieces produced with curved surfaces and complex shapes, and evaluate the surface shape and the manufacturing accuracy of specific position points. For this part of the inspection, the customer had used a certain model of three-dimensional scanner, but the actual measurement accuracy was not ideal, and the operation method of attaching points was relatively cumbersome, resulting in a relatively poor application experience.

Figure 2: API brand Radian Plus laser tracker

API laser tracker measurement solution

In response to the measurement requirements proposed by the customer and the measurement problems encountered in actual applications, the API team has provided the Radian Plus model laser tracker to "one-stop" meet the above many measurement requirements and solve the current difficulties and problems encountered.

The Radian Plus laser tracker is the fifth-generation laser tracker developed by the API brand. It has the performance characteristics of high accuracy (μm level), long range (measurement range over 160 meters), high integration and flexibility (main unit size 198mm×198mm×430mm, total weight less than 11kg), and can achieve completely wireless measurement (supports battery power supply, supports wireless data transmission).

During measurement, the operator holds a target ball with an integrated prism, and the Radian Plus laser tracker then emits a laser from the main unit to the center of the target ball and locks the tracking. The operator uses the target ball in hand to touch the points to be measured on the workpiece or slide it, and the Radian Plus laser tracker then measures the target point or trajectory with a high-precision static or dynamic data collection rate of 1000Hz and records it in real-time in the measurement software on the laptop for subsequent comparison and analysis.

After all target data is collected, lines, surfaces, volumes, and other spatial points can be constructed using the software. Additionally, numerical models can be imported, and by comparing measured values with theoretical or ideal values, the error values can be obtained, thereby achieving the purpose of measurement and detection.

In practical applications, the API combines with practice to design laser tracker accessory solutions for various measurement needs, such as deep hole and hidden point measurements (vProbe hidden point intelligent), rapid acquisition of large point cloud data (iScan3D scanning intelligent probe), and automated detection (ActiveTarget active target and STS six-axis sensor). This further expands the functionality of laser trackers and enriches the practical application scenarios.

Figure 3: Accessories of the API series laser tracker (from left to right: iScan3D intelligent scanning probe, ActiveTarget active target, STS six-axis sensor, vProbe hidden point intelligent probe)

Measurement site

On-site measurement of the inner diameter of a sleeve

As mentioned in the previous text, the test ring sleeve is made in an integrated manner, with high strength, large mass, and an inner diameter of 10 meters. Measurement is carried out using two large micrometers in conjunction, but due to various factors, the effect does not reach the expected level.

When using the Radian Plus laser tracker API for measurements, the operator simply needs to position the laser tracker at an appropriate location on the inside of the sleeve ring, connect it to a computer, and then start measuring. The operator holds a target ball and touches the inner wall of the ring sleeve to collect data, which is then immediately synchronized to the measurement software. This allows for the fitting and construction of the corresponding theoretical cylinder, from which the diameter, circumference, axis, and other geometric tolerance data can be calculated.

Figure 4: On-site measurement of the inner diameter of the annular sleeve

On-site measurement of position tolerance of non-standard workpiece holes and geometric tolerance of connecting surfaces

After the operator sets up the Radian Plus laser tracker at a suitable position around the irregular workpiece to be measured, the target ball is used in conjunction with the cylindrical pin measuring attachment to measure the points by fitting the hole wall, and the collected points are used to fit and construct circles. By combining this with the comparison of numerical models, the position error of the measurement hole can be determined. The shape and mutual relationships of other connecting surfaces, as well as the angular relationships between multiple planes, can also be evaluated and analyzed by fitting spatial points to construct corresponding planes. Additionally, the form and position tolerances of complex surface shapes can be analyzed by loading numerical models.

Figure 5: On-site measurement of hole position and connection surface geometric tolerance

On-site measurement of surfaces

On-site measurement of workpiece surfaces and complex shapes is similar to the process described above. By using a target ball with a laser tracker to collect spatial point coordinates, it is possible to compare the measured values with the theoretical values loaded into the model, thereby obtaining tolerances and achieving the purpose of measurement and detection.

Figure 6: On-site measurement of workpiece surface

More Extensions

In addition to the Radian Plus model laser tracker used in this case, the API brand has also developed a variety of models of laser trackers in response to actual application needs. For example: (1) The Radian Core model laser tracker can achieve basic measurement functions, providing a more economical investment option for customers with relatively simple measurement complexity requirements; (2) The Radian Pro model laser tracker, while using high-precision ADM absolute laser, also integrates IFM interference laser (the standard for length measurement, traceable), providing a testing instrument that meets the needs of production and laboratory sites with more stringent measurement accuracy requirements; (3) The iLT model, the latest sixth-generation laser tracker from the API brand, further reduces the overall size of the instrument to 152mm×152mm×330mm, with the main unit weighing less than 5kg. It demonstrates great convenience and environmental adaptability in fields such as automated integration, laser tracker array operations, and portable measurement.

Figure 7: API series laser trackers (from left to right: Radian Plus, Radian Pro, Radian Core, iLT)

Summary

The Radian series and iLT series laser trackers from the API brand, with their high precision, large range, small size, and ease of operation, fully meet the customer's needs for measuring and detecting the geometric tolerances of large and extra-large standard and non-standard castings in this case. They provide multiple guarantees to the customer in terms of measurement accuracy, process standardization, and measurement efficiency.

相关新闻:

API laser tracker is Application in the Inspection of Medium and Large Machined Parts

Project BackgroundClient Company: A large manufacturing enterprise;Industry: Hig

Radian laser tracker at Bucyrus 495HR Application of Mining Excavator Maintenance

Overview of Bucyrus 495HR Mining Excavator and Maintenance The Bucyrus 495HR min

Aerospace Composite Material Laying System Precision Detection Radian Laser Tracker Application Cas

About Aerospace Composite MaterialsAerospace composite materials are primarily u

3D Measurement Solutions for Large Oil Equipment

3D Measurement and Inspection of Large Oil EquipmentIn the oil equipment manufac

Learn More:

激光跟踪仪靶球&测头

Maximize laser tracker productivity with hand held and 激光跟踪仪主动靶标.

Learn More /laser-tracker-targets

XD Laser CMM Calibration

The XD Laser is the only assessment system that can measure all 6 error parameters simultaneously in a single set-up

Learn More /xd-laser

API Reverse Engineering Service

Reverse engineering services include scan as-built parts to creation of a 3D digital point cloud and CAD Model.

Learn More /reverse-engineering/

+86 10 59796858

+86 10 59796858