API laser tracker application of the tube sheet three-dimensional measurement solutions_API Measuring Instruments Inc.

Shield Tube Sheet & Tunnel Quality and Safety

Shield Tube Sheet is the main assembly component of shield construction, and it is the innermost barrier of the tunnel, which bears the role of resisting the soil pressure, groundwater pressure and some special loads. Shield tube sheet is the permanent lining structure of shield tunnel, and the quality of the tube sheet is directly related to the overall quality and safety of the tunnel, affecting the waterproof performance and durability of the tunnel. Therefore, the measurement and inspection of shield tube sheet is very important, which is the basic guarantee for the smooth implementation of the whole tunnel project, and its inspection requirements and standards are also very strict.

Inspection requirements

1. Flatness inspection of tube sheet

The change of flatness of end face and side face of tube sheet should be strictly controlled, if the change is too big, it will cause the assembly gap between rings and blocks, which will lead to tunnel leakage and other problems.

2, tube sheet internal and external arc length detection

tube sheet internal and external arc length over the limit, will affect the overall assembly, resulting in tube sheet extrusion or bumping, assembled tunnels are prone to misplaced and other problems.

3, the detection of the angle of the tube sheet

Angle changes will cause difficulties in connecting the tube sheet assembly, resulting in leakage of the bolt holes and other problems.

4, the detection of tube sheet mold

tube sheet molds in the production and later use, may produce deformation, such as can not be adjusted in a timely manner, will lead to the production of the quality of the tube sheet problems, further affecting the quality of the later assembly of the tunnel.

5, detection accuracy requirements

With the continuous improvement of engineering quality standards and safety requirements, the accuracy of the measurement and detection links in the production is also improving, the current stage of tube sheet detection accuracy is usually required to be 0.25mm.

Traditional detection methods

The traditional shield tube sheet, mainly using micrometers, sample boards, plug ruler and other gauges and tools for manual measurement. And the manual measurement method is more likely to have uncertainties in the following links:

(1) Manual measurement is more one-sided, can only measure the point-to-point results, it is difficult to more comprehensive feedback on the real situation of each position of the tube sheet or mold;

(2) It is difficult to guarantee the accuracy of the measurement of some complex angles;

(3) The construction site is often more complex changes in temperature and humidity environment, the temperature and humidity changes in the morning and evening and midday is easy to cause the thermal expansion and contraction of the material itself, and it is difficult to manually measure this part of the error into the comprehensive measurement results;

(4) Manual measurement for the operator's technical requirements, and different operators for the measurement techniques, reading skills, etc. It is difficult to maintain a high degree of consistency, resulting in an increase in the measurement of non-objective factors;

(5) Manual counting and calculation are cumbersome and complicated, and easy to make mistakes.

API Solution

For the characteristics of shield tube sheet and mold, using API brand Radian and iLT series laser tracker for 3D measurement can realize all the measurement needs, and it is more objective and efficient than the manual inspection method.

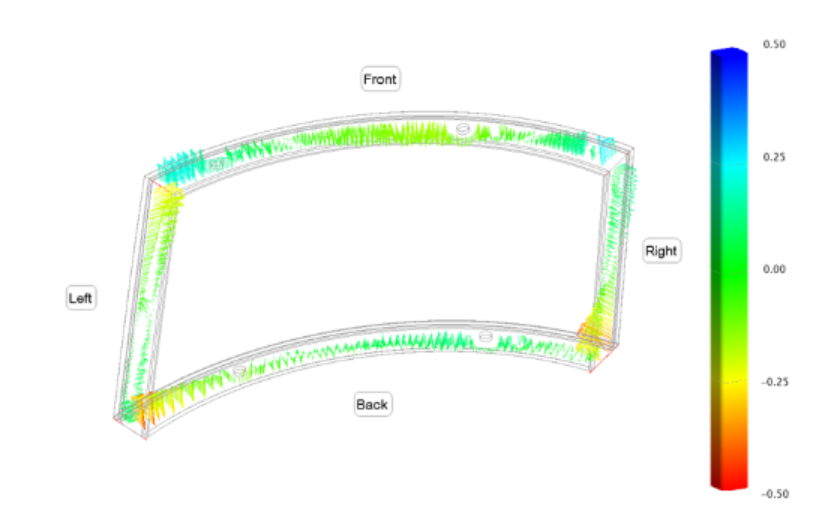

Simply set up the Radian or iLT laser tracker in a suitable position next to the tube or mold to be measured and start measuring. During the measurement, the operator holds the tracker target ball (SMR) with built-in prism, the laser tracker will shoot the laser to the center of the target ball and lock the tracking in real time, the operator only needs to touch the target ball to the point to be measured, or slide the target ball to fit the surface to be measured, the API tracker will collect the three-dimensional data of the position to be measured at the acquisition rate of 1000Hz with high accuracy and efficiency, and provide feedback and recording in the software for the final analysis. The data will be recorded in the software for final analysis. When all the data have been collected, the corresponding reference points can be selected in the software to construct various lines, surfaces and bodies, analyze the shape and position tolerances, and load the digital model to compare the measured value with the nominal value to achieve the purpose of inspection.

Compared with the traditional manual measurement method, the use of Radian laser tracking instrument to implement the inspection operation of the tube sheet has obvious characteristics and outstanding advantages:

- Real-time measurement, intensive acquisition, fully reflecting the real condition of the tube sheet or mold;

- Complex angles and irregular surfaces can also be accurately measured;

- Integration of temperature and humidity compensation system (weather station), temperature, humidity, altitude and other error factors are automatically compensated;

- High repeatability of measurement can be realized even by different operators, and the inspection data is more objective;

- Automatic analysis of data, reducing the calculation error rate to zero;

- Automatically generates measurement reports in the form of lists, line graphs, color difference graphs, bar graphs, etc., which is efficient and intuitive;

- Large measuring range and micron-level (μm, 1/1000mm) measurement accuracy to fully meet the needs of tube sheet and mold inspection accuracy.

Summary

To sum up, API laser tracker is powerful and friendly to operate, which can completely replace the traditional manual measurement method, and become a more accurate, objective, efficient and convenient inspection method for shield tube sheet/mold.

相关新闻:

API laser tracker is Application in the Inspection of Medium and Large Machined Parts

Project BackgroundClient Company: A large manufacturing enterprise;Industry: Hig

Radian laser tracker at Bucyrus 495HR Application of Mining Excavator Maintenance

Overview of Bucyrus 495HR Mining Excavator and Maintenance The Bucyrus 495HR min

Aerospace Composite Material Laying System Precision Detection Radian Laser Tracker Application Cas

About Aerospace Composite MaterialsAerospace composite materials are primarily u

3D Measurement Solutions for Large Oil Equipment

3D Measurement and Inspection of Large Oil EquipmentIn the oil equipment manufac

Learn More:

激光跟踪仪靶球&测头

Maximize laser tracker productivity with hand held and 激光跟踪仪主动靶标.

Learn More /laser-tracker-targets

XD Laser CMM Calibration

The XD Laser is the only assessment system that can measure all 6 error parameters simultaneously in a single set-up

Learn More /xd-laser

API Reverse Engineering Service

Reverse engineering services include scan as-built parts to creation of a 3D digital point cloud and CAD Model.

Learn More /reverse-engineering/

+86 10 59796858

+86 10 59796858