Laser Tracker Measurement

Laser tracker is large size 3D/6D measuring equipment, have been world-widely used in the measuring and inspection field in high-end manufacturing areas, especially used for static point high-precision measurement, dynamic trajectory monitoring, alignment, assembly and positioning, played as an irreplaceable role.

When we use laser tracker to measure a target, normally, the operator handle takes the SMR (laser tracker target ball) to touch the target location need to be measured, and the laser tracker's laser beam locked at the center of the SMR, and will take the data when SMR touches the target location, the data will be send to PC software at the same time, when all data collected well, we can use the data for CAD comparison or modeling.

In addition to the SMR, the laser tracker is usually equipped with accessories for hidden points measuring and laser line scanning. These accessories expanded laser tracker application, as well as provided efficiency guarantee for both plant and laboratory precision measurement tasks.

As the inventor of the laser tracker, API not only providing high quality laser tracker hardware, but also developed a number of laser tracker application and practical function, software, and methods, to further expand the application of the tracker, aims to provide convenience for tasks that not easy to implement by using normal ways, to make a combination between both accurate and efficient.

Laser Tracker Multi-SMR Automatic Measurement

Multi-SMR automatic measurement is a representative of the API developed laser tracker practical measurement function.

This function uses iVision (artificial intelligence active vision system) of Radian Pro, the flagship model of API laser tracker, which provides a feasible way to realize accurate automatic measurement for tasks that are not convenient for personnel to contact the position to be measured in actual measurement operations.

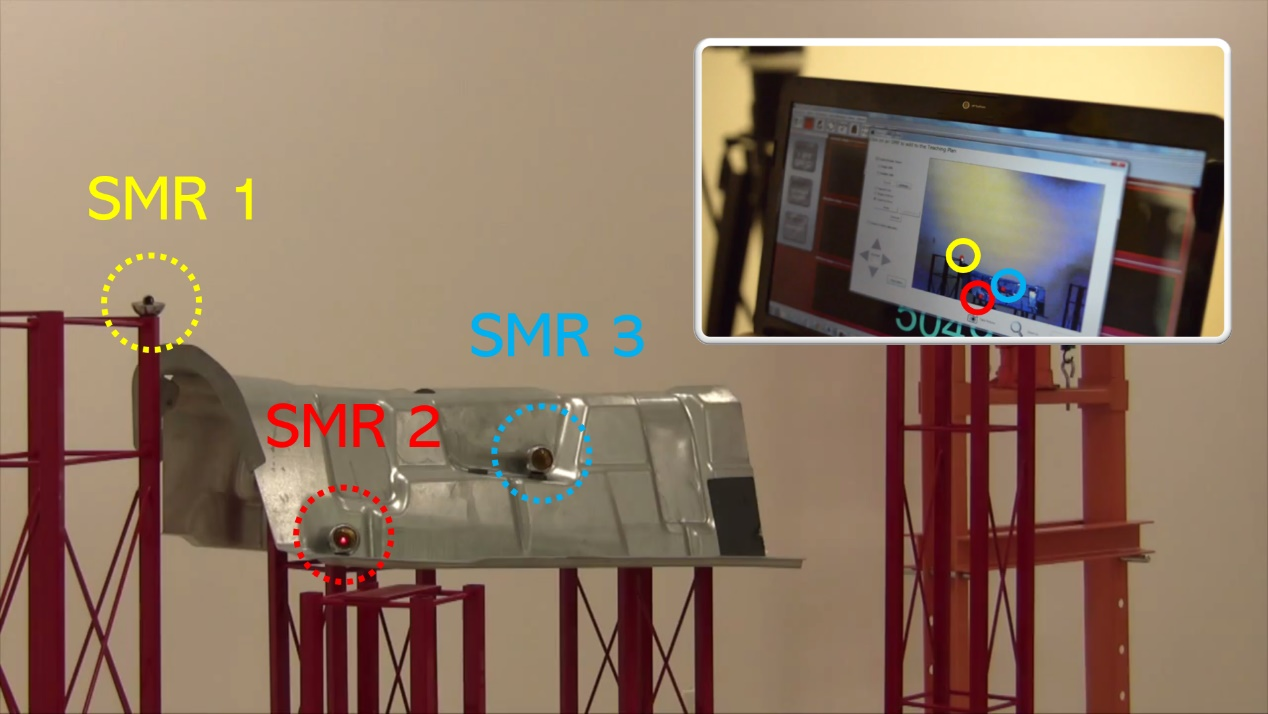

Figure 1: The position of the target to be measured and its display in the software (upper right small picture)

Radian Pro laser tracker integrated with intellectual active vision system, can observe multiple targets (SMR) in the field of vision at the same time, the operator instructions, or pre-programmed automatic execution, in accordance with the planned time point or order to identify and measure the selected target. (as shown in Figure 1)

Case Study

Research topic of a scientific research institution: need to load different weights in different positions of the workpiece to achieve balance and monitor the 6DoF variation of the workpiece.

In order to meet the measurement needs of this topic, if use the traditional measurement mode, which can be used to measure the different targets on the workpiece manually, and calculate the six degrees of freedom change information of the workpiece. However, using the traditional mode is time-consuming, the measuring time of one position with one weight is more than 3 minutes, and the whole operation needs to be measured with hundreds of sets of data. If using the traditional mode, it is difficult to ensure the efficient implementation of the whole operation.

The application of Radian Pro laser tracker multi-SMR automatic identification measurement function not only ensures the high accuracy of the whole measurement operation, but also guaranteed high efficiency for the operation implementation.

Figure 2: Placement position of laser tracker (lower right small picture) and arrangement of points to be measured on the workpiece

In the operation, after the laser tracker and the target points are installed (as shown in Figure 2), the Multi-SMR automatic identification and measurement program can be triggered together with the SDK that joint developed with the scientific research institution: When the weight loading is completed, the laser tracker automatically measures the points arranged on the workpiece one by one, and calculates the 6DoF variation by matrix algorithm for subsequent analysis and compensation.

The achievement: the measurement time is saved by 90%, and completely avoided the possible errors that caused by operator mis-touch.

The final results achieved: the angle precision controlled in 0.01°, and the spatial position precision controlled in 0.03mm. This result achieved the research purpose of this topic.

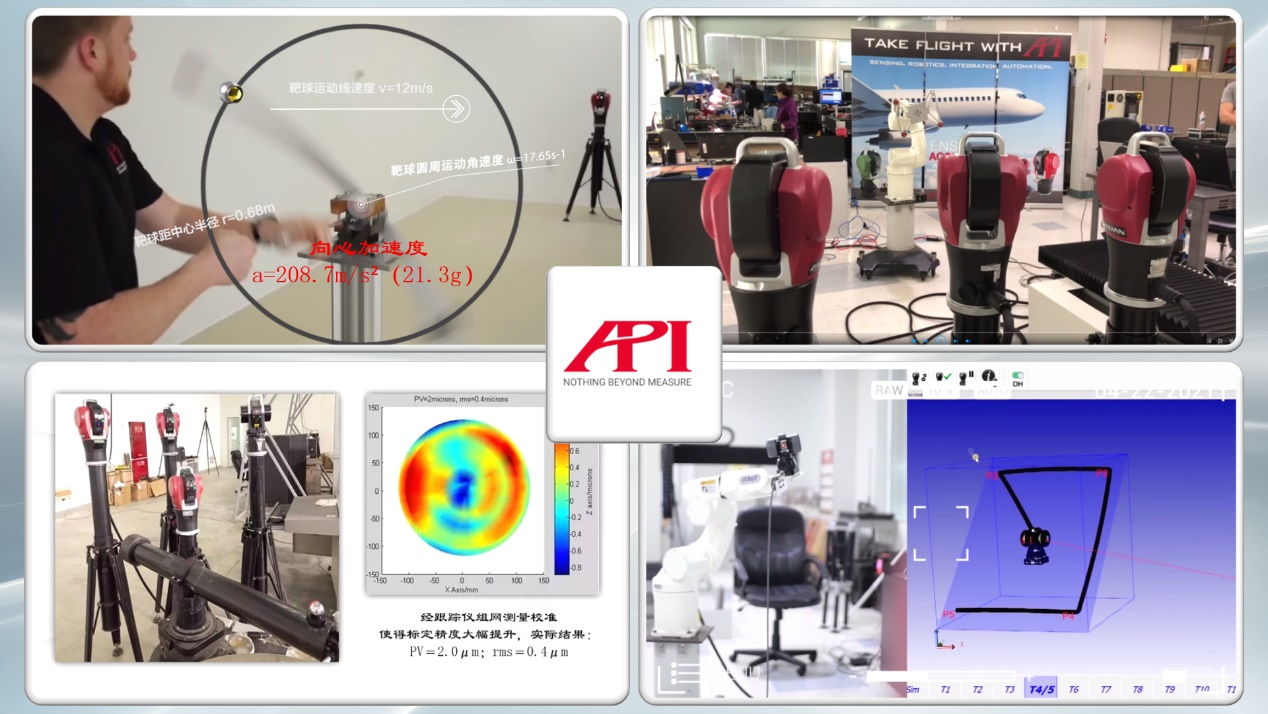

Figure 3: advanced application of API laser tracker: precise measurement of high-speed moving targets (upper left), network measurement of multiple laser trackers (upper right), extreme high-precision measurement of single position by multiple laser trackers (lower left), dynamic measurement by 6DoF STS sensor (lower right)

Conclusion

Multi-SMR automatic identification and measurement function well provided a feasible way to realize accurate automatic measurement for tasks that are not convenient for personnel to contact the position to be measured in actual measurement operations.

In addition to the Multi-SMR function, API also provide advanced laser tracker application functions: precision measurement of high-speed moving targets, network measurement of multiple laser trackers, extreme high-precision measurement of single position by multiple laser trackers , dynamic measurement by 6DoF STS sensor etc. Please contact API for more details.

相关新闻:

API laser tracker is Application in the Inspection of Medium and Large Machined Parts

Project BackgroundClient Company: A large manufacturing enterprise;Industry: Hig

Radian laser tracker at Bucyrus 495HR Application of Mining Excavator Maintenance

Overview of Bucyrus 495HR Mining Excavator and Maintenance The Bucyrus 495HR min

Aerospace Composite Material Laying System Precision Detection Radian Laser Tracker Application Cas

About Aerospace Composite MaterialsAerospace composite materials are primarily u

3D Measurement Solutions for Large Oil Equipment

3D Measurement and Inspection of Large Oil EquipmentIn the oil equipment manufac

Learn More:

激光跟踪仪靶球&测头

Maximize laser tracker productivity with hand held and 激光跟踪仪主动靶标.

Learn More /laser-tracker-targets

XD Laser CMM Calibration

The XD Laser is the only assessment system that can measure all 6 error parameters simultaneously in a single set-up

Learn More /xd-laser

API Reverse Engineering Service

Reverse engineering services include scan as-built parts to creation of a 3D digital point cloud and CAD Model.

Learn More /reverse-engineering/

+86 10 59796858

+86 10 59796858